Introduction

The landfill of Reykjavik, Iceland has implemented for the last decade an active collection of the landfill gas (LG) in order to produce upgraded biomethane used as transportation fuel in the capital area. In 2016, 1.900.000 Nm3 of upgraded biomethane was produced and sold in fuel stations in the capital area. In order to fulfil the increasing demand in biomethane, it is necessary to collect more LG while keeping the methane content in the upgraded gas as high as possible (≈95% CH4). Increasing LG recovery while keeping biofuel grade can be achieved by combining the extension of the gas collection area and use methods to increase the efficiency of the existing system.

Goal and scope

Production of methane biofuel requires a high composition of biomethane (>95%). In order to reach such composition and based on a water scrubbing technology for upgrading, it is necessary to limit Nitrogen and Oxygen content within the landfill gas. In addition, to avoid landfill gas emission and to answer the market demand, it

Description of Álfsnes landfill site

Reykjavik landfill can be seen as a series of bioreactor systems. Each of the cells is closed with a soil cover and waste composition and age is known. The gas collection system is installed usually in a period of 0,5-2 years after the closure of the cell. In addition, the older part of the landfill equipped with a gas collection system is used as a test area for leachate recirculation.

The extension of the area where LG is collected is limited by the filling rate of the landfill on one side and by ageing cells where gas production is almost nonexistent on the other side. Therefore, the best room for improvement in quantity and quality relies on the optimization of the operating system. To achieve quality and quantity goals, an advanced monitoring plan of the landfill was implemented since the year 2014 with the collaboration of the Environmental Engineering company ReSource International (RSI) ehf. and the landfill operator SORPA bs. The monitoring plan is implemented as a multi-layer strategy including spatial and temporal considerations.

Our strategy and method

In the past focus was put on upgrading and following the gas composition of the collection lines and wells. Our approach was change and the focus was made on the source of the gas i.e. the landfill body and how each well was behaving bringing a more active and controlling strategy on the source.

The groundwork of the monitoring plan includes a monthly monitoring of the highly dense collection wells network. Over an area of 32 ha, 152-180 wells are in an active collection. Wells form a collection grid with a mesh size of approximately 15-20m. Parameters such as gas composition, suction pressure at the wellheads and within the collection lines and temperature and level of the leachate are measured for each well on a monthly basis.

| Type | Name | Frequency | Extend/Scope | Equipment |

| Gas concentration | Gas composition (quality) wells | Monthly | Each well | GA5000 Gas analyzer |

| Differential pressure well heads | Gas flow wells | Monthly | Each well | GA5000 Gas analyzer |

| Leachate level | Leachate level within gas wells | Every 3 months | Each well | Contact gauge for water/leachate level and temperature |

| Leachate temperature | Leachate temperature within gas wells | Every 3 months | Each well | Contact gauge for water/leachate level and temperature |

| Water level | Groundwater level in groundwater wells | Every 3 month | Each groundwater borehole | Contact gauge for water/leachate level and temperature |

In addition to these manual measurements, automatic measurements (10min) are also done on the leachate collection system, weather parameters and the upgrading station.

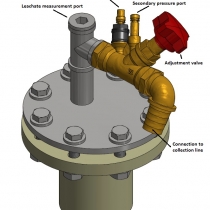

The second part of the method includes the adjustment of the gas well and their collection capacity. Based on parameters and data history the adjustment valves on the wells are adjusted with the following considerations:

Results

DIRECT RESULTS ON GAS COMPOSITION AND OPENING ON THE SYSTEM

After 3-4 months it was possible to see already trends within the wells behaviours. Some closed wells were being opened and the one open were being even more open. Over the first year, it was possible to realize seasonality of the wells behaviours. Also “low hanging fruits” in maintenance failures could be pointed out and solutions solution could be implemented rapidly.

LONGER TERM RESULTS

A year after the project started, it became possible to analyze data over time in order to optimize the LG collected and the design and the maintenance of the gas collection system. In addition, analyzing data provides information on the correlation between LG composition and external parameters such as atmospheric pressure, landfill cover humidity and spatial position of the wells within the landfill body, activeness of the landfill, etc. After 2 years most of the monitored wells for this period of time suggested that they had reached their actual capacity.

An example of a well that has been continuously opened since installation

An example of a well usually closed that could be reopened until it reaches its limits

IMPACT ON MAINTENANCE

Maintenance of the gas collection system today is directly related to monitoring results. Thus each task is prioritized and more efficiently carried. Maintenance is also participating in the optimization of the system and help to improve quality of the gas.

Additional monitoring

In year 2 and 3, drone surveys are also becoming part of the regular measurement plan. With photogrammetry surveys (RGB) it is possible to get georeferenced DEM and aerial maps of the landfill site with accuracy down to 3-5 cm. Then it is possible to plot data in a 3D representation of the landfill enhancing comprehensiveness for the operator. Geodata is also used to plan and control the landfilling process with fast and accurate volume and height measurements. Drone platforms also offer the possibility to measure near-infrared emission for vegetation growth helping to maintain vegetation cover on the landfill.

Future developments

The monitoring of the landfill is a continuous and iterative process. Building knowledge allows us to go deeper and further and findings and methods can be applied to other sites. For Reykjavik site the next steps could be:

- Keeping the system up to date and running

- Use it even more for maintenance and planning of the gas collection system

- Improving original design of the system

- Install wireless sensors on the landfill body to monitor additional parameters such as soil moisture, groundwater level, gas escaping, etc.

- Continue to develop drone based methods for assessing operational parameters (Volume, DEM, vegetation, thermal activity, methane leaking, etc)

- Develop a web-based tool that can be applied to other landfill sites as well

Acknowledgement

The content of the work presented on this page is a summary of the 3 years collaboration between the municipal solid waste management company of the Great Reykjavik, SORPA bs. and the environmental Engineering company ReSource International ehf. Thanks to SORPA’s support and interest we have managed to develop together good knowledge of the site and reach our goals to maintain the quality of the process. The initial version of the 3D model presented on this page is the results of the work from Rossana Gloriosi and Gianni Cordaro from the University of Florence.

Keywords: Landfill gas collection system, biomethane, system optimization, smart technology, data analysis, 3D dimensional analysis, drones, thermal imaging, Internet of Things